ITS5300 battery charge and discharge test system isdesigned for a variety of power batteries (lead acid, nickel hydrogen, lithiumbatteries, super capacitors, hydrogen fuel cells, etc.) for performancetesting. ITS5300 test system can be used in performance testing of a hundred ormore battery packs or 200 cells in the battery packs at one time, remarkably improving the testing efficiency and capacity of the productionline. ITS5300 test system consists of ITECH powersupply, electronic load, internal resistance tester, temperature acquisitionand other products with professional battery test software components, highdegree of automation and high stability. ITS5300 is the best choice for user testing.

Reliable and Discharging Performance Test of Battery Back

Test Items-Battery cell and battery pack

♦Internal resistance test: online/offline AC/DC IR test.

♦Charge and discharge performance test, curve depictedautomatically.

♦Temperature test

♦Life cycle test

♦Capacity test

ITS5300 Test Software

ITS5300 test software has ultrafast response and 50 kHz I/Vsampling rate. One set of software can test hundreds ofbattery pack simultaneously. ITS5300 software has a lot offunctions, e.g. power-off memory protection, complete charge&discharge protection, data backup, configuration of useraccess rights, various step editing, optimized report andanalysis functions, data Excel export, easy programming etc.

Seamless switching between 2quadrants/ Charge & Discharge test

Work with IT-E500 power dissipater unit, IT6500C greatly expands the sinking current andpower, which can be widely applied in bidirectional current test or battery system charging/discharging test. Each IT-E500 series power dissipater unit can sink up to 3 kW. By parallelingmultiple power dissipater units, the sinking power can reach up to 300% (Max.90 kW) ofsource power, which can meet the requirement of high power test.

Battery Internal Resistance Test

Generally, battery pack is composed of several battery cell connected in series. ITECH integrated power battery test solution includingbattery internal resistance test, battery pack reliable test and discharge performance test, battery module performance and function test,vehicle simulation test.

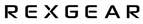

Measurement of DC Internal Resistance

For high-capacity batteries applications, such as powerbatteries, it is inconvenient or impossible to test the ACIR.So generally battery pack is assessed by its DCIR. DCIRtesting includes resistances of electrolyte, battery leadplate, and polarization reaction.

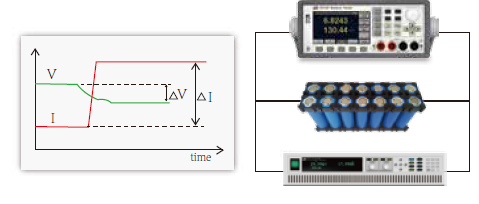

Measurement of AC Internal Resistance

A battery pack is typically multiple battery cells in serialconnection. A sharp difference between the cells may greatlydamage the battery pack’s capacity and dischargeperformance. Therefore, measurement and systematicanalyse of cell IR is an important part of battery performancetest and it is a must test item for power battery. The batteryIR is not a constant value and it keeps changing whilecharging and discharging. The dynamic IR and voltage ofeach cell can be tested simultaneously by on-line IR testerIT5102, so as to monitor whether any battery has failed.

Recommend Hardware

Dynamic Simulation Test

Electric Vehicle Battery Test - Braking Current Regenerative Simulation

When electric vehicle brakes, to reach the same effect of petrol cars braking,the output I/V curve of EV battery should follow a deceleration curve standard.For practical EV battery test, the simulation of bidirectional braking current isnecessary, and the test time should be within 10ms. So the reliablity of the testdepends on the response speed of test instrument.1- Traditional solution: Adopt two separate units, such as a DC Power Supplywith an Electronic Load, which has a lot of drawbacks, such as complicatedsystem construction, incontinuous voltage waveform and often cannot reachthe testing requirement for speed;2- ITECH solution: IT6500C provides fast and seamless switching betweensourcing current and sinking current, with support of power dissipater unit,IT6000C can extend sinking current and power. It is an ideal solution forbidirectional and regenerative energy system test, such as braking current,battery system, etc.

Dynamic Discharging Test

When an electric vehicle is moving, its battery discharging waveform isdynamic changing, the dynamic discharging test can simulate thedischarging status of the electric vehicle battery and calculate the remainingmileage.IT8700 and IT8000 series regegenerative electronic load have 25 kHz dynamic mode.Adjustable current rising/ falling speed in List mode supports user definedcurrent changing, which is suitable to simulate EV battery working status.Moreover, IT8000 series can control the load current via external analoginterface with fast response time, which complement the List function.

Recommend Hardware